One-way capture means lost energy

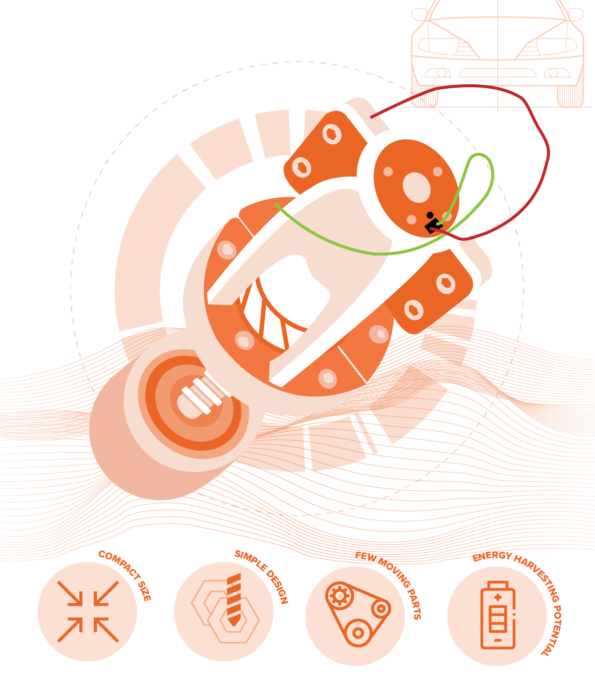

Regenerative shock absorbers (RSAs) are used to convert the repeating linear motion of a mechanical object – usually a vehicle – into energy. Although these are highly useful, creating free and renewable power, they are usually only harnessing a percentage of the energy that is available to them. By using a conventional single threaded screw at the heart of the mechanism, the rotational output motion – which feeds into the generator – is naturally dependent on the direction of the linear input and leads to output which varies constantly with the direction of motion.

To capture this lost potential there needs to be a solution design that is more efficient in capturing all the motion generated energy and – given the possible applications – compact enough to be accommodated in existing mechanical designs without impacting performance or experience.

Kinetic to electric – with endless possibilities

The SRS-EH RSA mechanism design delivers a solution with a self-reversing screw (or a diamond-thread screw) that enables accompanying nuts and clutches to automatically reverse its travel direction whilst retaining the relative rotation of the screw, effectively converting any random vibration into a continuous rotational motion. By converting intermittent translational motion (e.g. the rise and fall of waves, the movement over terrain of a vehicle, the impact of feet on a surface), the unique design captures a continuous flow of energy and transfers it via the flywheel into a generator.

The SRS-EH design is compact, easy to manufacture, and efficient, and provides a viable and sustainable replacement for conventional shock absorbers, particularly providing greater ranges for electric vehicles, and delivering high potential for harnessing wave energy. The SRS-EH also has the potential to efficiently harvest new power sources, such as the movement of bridges, buildings, and the vibration of sports and pedestrian surfaces.

25% of all energy consumption comes from transportation. Transportation of people and goods accounts for 25% of all global energy consumption with passenger vehicles making up most of that.

3.8kw power lost per engine. Rail vehicles’ primary and secondary dampers are key causes of energy loss, with a total dissipated power ranging from 3.5 to 3.8 kW per vehicle.

$452 Million global energy harvesting system market. In 2020 the global energy harvesting system market size was valued at $452.2 million and is expected to grow 10.2% per annum between 2020 and 2028.

From the Inventor and Project Lead

I see this invention having the potential to benefit the automotive, rail transport, marine, and energy supply sectors both in the UK and around the world. I am delighted that we have such clear interest already from Unipart (Rail & Automotive) and Wave Energy Scotland, and we are eager to find the right partner to help us take the design into the next phase of development and move it to market as quickly as possible.

Progress

Prototype built and efficiencies proven, SRS-RSA is preparing for field testing

The SRS-RSA patented designs have been proven to outperform other products, particularly in the areas of mechanical efficiency, compactness, and the amount of energy it can harvest. A simple prototype has been tested and plans are underway to test an MVP in the field.

Potential partners engaged

Two potential sponsorship partners have already expressed interest. The innovation has support from Unipart Automotive & Rail and Wave Energy Scotland who have backed the SRS-RSA Engineering and Physical Sciences Research Council (EPSRC) award proposal.

Interest across multiple industries

With alternative energy companies, such as Pavegen, already showing interest in the SRS-EH design, the potential for application across multiple industries is clearly being recognised.

Patents filed to protect the design

Two patents have already been filed to protect the design of the SRS covering both the Regenerative Shock Absorber (SRS-RSA) and the Self-Reversing Screw Energy Harvester (SRS-EH). The self-reversing screw (SRS) is the central, unique component to both these patents.

Meet the SRS-RSA Team

Originator, inventor, and lead of the SRS project, Dr Torbati holds the patent for both elements of the design. He is an Associate Professor in the Mechatronics Research Group, Mechanical Engineering Department, Faculty of Engineering and the Physical Sciences, University of Southampton, and his research activities are in areas of energy harvesting and storage, structural optimisation, active and passive control, Material Characterisation, and fractional calculus. Dr Torbati is also a Senior Consulting Engineer with over 20 years of experience of carrying out consultancy projects for industrial clients. His recent big projects were on energy harvesting from road surfaces.

More information

We are looking for partners who recognise the vast potential of this design to provide investment and support to take us forward into the next stage. With patents already filed to protect the design, and simulations proving both the viability and the efficiency gains from this specific design, we are in an excellent position to begin to test and develop the mechanism for real world scenarios.

In vehicles, suspensions with RSA can increase lifetimes of batteries for electrical and hybrid vehicles, improve fuel efficiency and reduce exhaust emissions, thus achieving up to 10% greater fuel efficiency. With electric and hybrid vehicles central to the future of road-based travel – and set to dominate the new car market in the UK from 2030 onwards – SRS-RSAs will prove a highly valuable addition offering a sustainable energy solution for range extension and greater efficiency.

The commercialisation of the technology has the potential to create employment opportunities in the manufacturing, testing, and selling of the device to major vehicle manufacturers. The automotive suspension market is projected to grow at a CAGR of 3.88% during the forecast period, from $50.76bn in 2017 to $68.84bn by 2025. The active suspension system is the fastest growing market, by system, in terms of value, meaning the design has the potential to return the leadership of this market to the UK as well as taking a portion of the market generating substantial surplus.

In marine industries, despite huge efforts made to develop efficient wave energy extraction technologies, their commercialisation is still seriously behind other sources of renewable energy such as wind and solar energy with no champion technology being identified. A wave energy concept with gears-based mechanical motion rectification has already demonstrated its viability by securing over $2M at its commercialisation stage. Our invention will significantly improve the reliability and efficiency of such a wave energy converter, thereby directly reducing its maintenance cost and levelised cost of energy.

Our investigations into the application of the SRS-RSA for rail vehicles, show that the design has the potential to replace conventional dampers, exhibiting better dynamic performance whilst generating greater power. With more research to evaluate the function of the Self Reversing Screw design in the functional context of a rail vehicle we will be able to qualify the energy harvesting potentials for different vehicles depending on both vibration intensity level and vehicle size.

One area that may be of great interest is to design self-powered sensors using this invention. These sensors can be used either on trains or on trackside when energy is harvested from railway sleepers.